FJTMKC-10E High precision slot cutter for pipe expander

exhaust pipe expander kit, 5 inch exhaust pipe expander, exhaust pipe spreader

50000pcs everyday

ISO9001

1 year

100pcs

TT/LC/Western Union

One week after payment

TMKC-10E High precision slot cutter for pipe expanderB

The tube plate inner hole slot cutter is referred to as the slot cutter, also known as the slot cutter, the slot cutter, and the slot cutter, which is a special tool for the hole slot of the tube plate before the expansion of the tube. After the opening of the pipe hole, the sealing and pulling force of the connection between the pipe and the tube plate after the expansion of the pipe system are increased, and the connection strength with the pipe is greatly improved, which is not easy to loosen and stretch. It can also reduce or eliminate the expansion problems and troubles caused by the gap or porosity caused by the thermal expansion and cold contraction of the expanded pipe or other factors. The precision of slotting in the tube plate directly affects the quality of the expanded tube. A, B, C, E series slotting device, is to meet the hydraulic strength expansion requirements of the heat exchanger tube plate hole slotting special equipment.

With the wide application of hydraulic strength expansion technology, the requirements for tube plate slotting are getting higher and higher, and the simple slotting device made by users can not meet the requirements of 8-12mm wide grooving for hydraulic strength expansion. Therefore, in order to solve the problem of this part of users, the company has successfully developed a tube plate slotter that can meet the requirements of hydraulic strength expansion slotting.

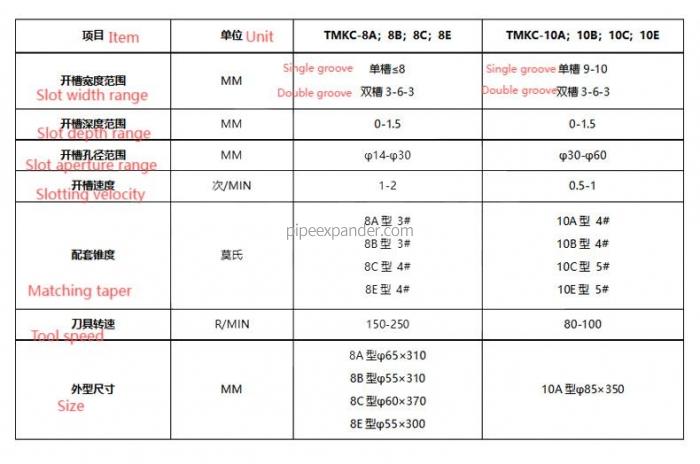

TMKC-8A, 8B, 8C, 8E, 10A, 10B, 10C, 10E series of slotting, is to meet the hydraulic strength expansion requirements of the heat exchanger tube plate hole slotting special equipment, it is our company using the United States and domestic advanced technology, self-designed and improved a multi-purpose slotting device.

They are composed of three parts: (1) the main body, (2) the tool bar, and (3) the blade.

According to customer requirements can choose different types of slotting machine, tool rod and blade are customized according to user requirements. The tool bar is customized according to the aperture, and the blade is customized according to the slot width.

Features:

1, High production efficiency;

2, Automatic positioning, to adapt to the common specifications of pipe hole grooving;

3, High slotting quality and good reliability;

4, According to the requirements of hydraulic expansion slotting; Various shapes of slotting tools can be selected at will.

The main working principle of the screw slotter is to adopt the eccentric structure of the tool bar and the reversing structure of the spiral groove. The sliding pin set in the spiral groove drives the tool bar to rotate radially to the set Angle, so as to raise the tool head to complete a slotting process. The tool has the advantages of uniform and smooth grooving depth, stable performance, high strength and long service life. It is especially suitable for grooving belt machining with multiple grooves, high coaxiality requirement or wide grooving belt and high grooving strength. It also has good performance on tube plates with higher hardness such as stainless steel. Can replace imported tools.

Advantages: high strength, high precision, good versatility. The position and depth of the slot can be easily obtained by adjusting the adjusting nut, which is very convenient; When used for multi-slot cutting, the depth between the slots is exactly the same.

Use: It can dig out all types of grooves in the plate hole at one time, and can precisely control the depth of the grooves, the groove surface is smooth and smooth, and can be used on equipment such as radial drilling machine. It is an effective tool for grooving in the tube plate holes of some high-pressure or high-sealing containers in the electric power, petrochemical, refrigeration and steam turbine manufacturing industries.

Features:

1, High production efficiency;

2, Automatic positioning, to adapt to the common specifications of pipe hole grooving;

3. High slotting quality and good reliability;

4, According to the requirements of hydraulic expansion slotting; Various shapes of slotting tools can be selected at will.

The main working principle of the screw slotter is to adopt the eccentric structure of the tool bar and the reversing structure of the spiral groove. The sliding pin set in the spiral groove drives the tool bar to rotate radially to the set Angle, so as to raise the tool head to complete a slotting process. The tool has the advantages of uniform and smooth grooving depth, stable performance, high strength and long service life. It is especially suitable for grooving belt machining with multiple grooves, high coaxiality requirement or wide grooving belt and high grooving strength. It also has good performance on tube plates with higher hardness such as stainless steel. Can replace imported tools.

Advantages: high strength, high precision, good versatility. The position and depth of the slot can be easily obtained by adjusting the adjusting nut, which is very convenient; When used for multi-slot cutting, the depth between the slots is exactly the same.

Use: It can dig out all types of grooves in the plate hole at one time, and can precisely control the depth of the grooves, the groove surface is smooth and smooth, and can be used on equipment such as radial drilling machine. It is an effective tool for grooving in the tube plate holes of some high-pressure or high-sealing containers in the electric power, petrochemical, refrigeration and steam turbine manufacturing industries.

Matters needing attention

1, The grooving process, the speed can not be too high, so as not to damage the tool and parts.

2, Fixed blade bolts must be tightened, but not too hard!

3, When grooving, the tool should be free to position the workpiece, otherwise it will cause grooving eccentricity.

4, The sliding part should maintain good lubrication performance. Lubricating oil should be filled frequently and kept clean without stuck phenomenon.

5, Fill bearing lubricating oil regularly.

6, The selection of tool rod and tool should be within the parameter range.