Product Introduction

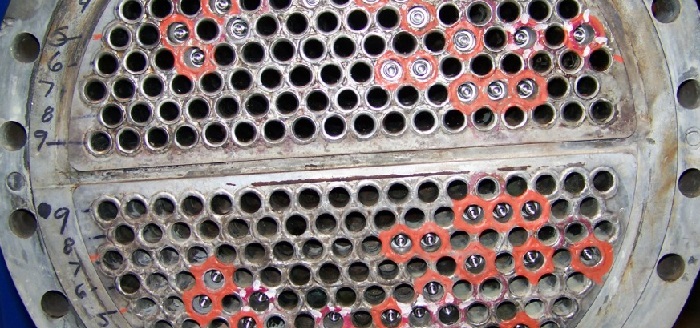

The FJPOP-B-PLUG P2 high-pressure heat exchanger tube plug delivers the permanent performance of explosive or welded plugs while saving significant time and cost compared to competing leak sealing technologies.

Features & Benefits

High Installation Expansion Range: Each plug covers 0.02 inches (0.51 mm)

Easy Measurement: Includes go/no-go gauge for tube measurement and plug selection

Standard Sizes & Materials:

Suitable for tube IDs from 0.400-1.460 inches (10.16-37.08 mm) in brass (B), carbon steel (C), 316 stainless steel (S), Monel (M), and cupronickel (N). Contact factory for larger sizes or special materials

Simple Installation: Unique separation mechanism controls installation force. Operator prepares tube, inserts plug into leaking tube end, and pulls plug using hydraulic puller

Hydraulic Installation: Installed using the Pop-A-Plug P2 system hydraulic puller package

Sealing Performance: Helium leak-tight seal up to 1×10⁻¹⁰ cc/sec

Ordering Information

When ordering, specify: tube OD and wall thickness, or tube ID; tube and tube sheet materials (if plug installs directly into tube sheet); maximum pressure and temperature; tube type at tube sheet joint (rolled, welded, etc.); tube condition; and heat exchanger service years. Specifications subject to change.

Quality Assurance System

Manufactured under quality assurance programs including ISO 9001:2000 certification and several US nuclear industry standards: ANSI N45.2, NQA-1, 10CFR 50 Appendix B, and 10CFR 21.