Heat exchangers are critical equipment in industrial production, widely used in sectors such as chemical, petroleum, power, and pharmaceutical industries. However, during long-term operation, internal tube bundles often accumulate fouling due to various reasons. This fouling not only reduces the heat transfer efficiency of the exchanger but also increases energy consumption and maintenance costs. Therefore, regular cleaning of the internal tube bundles in heat exchangers is particularly important. In recent years, ultra-high pressure cleaning machines have been widely adopted for removing fouling from heat exchanger tube bundles due to their high efficiency and environmental benefits.

Working Principle of Ultra-High Pressure Cleaning Machines

Ultra-high pressure cleaning machines utilize high-pressure water pumps to pressurize ordinary water to levels ranging from hundreds to thousands of bars, generating high-speed jets that impact and clean surfaces through specialized nozzles. Under the force of these jets, fouling layers are dislodged and carried away by the high-pressure water flow, achieving the cleaning objective. Additionally, depending on actual requirements, cleaning agents or hot water can be introduced as auxiliary media to enhance cleaning effectiveness.

Advantages of Ultra-High Pressure Cleaning Machines for Tube Bundle Fouling Removal in Heat Exchangers

1. Superior Cleaning Performance

The high-pressure water jets generated by ultra-high pressure cleaning machines penetrate deeply into tube interiors, enabling comprehensive 360° cleaning of the inner surfaces without blind spots. This effectively removes all types of fouling and deposits, including hardened scales and stubborn contaminants.

2. High cleaning efficiency: The cleaning speed of ultra-high pressure cleaning machines is significantly higher than that of traditional manual cleaning and mechanical cleaning, which can greatly improve cleaning efficiency and shorten the cleaning cycle.

3. Environmental Protection and Energy Efficiency: The ultra-high-pressure cleaning machine uses high-pressure water streams for cleaning, eliminating the need for chemical cleaning agents and thus reducing environmental pollution. Additionally, the low friction generated by the high-pressure water streams during the cleaning process results in lower energy consumption.

4. Easy to operate: The ultra-high pressure cleaning machine features an automated control system, making it simple and convenient to use and thereby reducing the labor intensity for workers.

Application Scope of Ultra-High Pressure Cleaning Machines in Heat Exchanger Tube Bundle Cleaning

Ultra-high pressure cleaning machines are suitable for cleaning heat exchanger tube bundles with minimum internal diameters of 8mm and maximum internal diameters of 32mm. Within this range, the high-pressure water jets can fully perform their function, effectively removing internal fouling and deposits. Furthermore, these machines can adjust both cleaning pressure and media according to the specific tube material and deposit characteristics to achieve optimal cleaning results.

Parameter Information

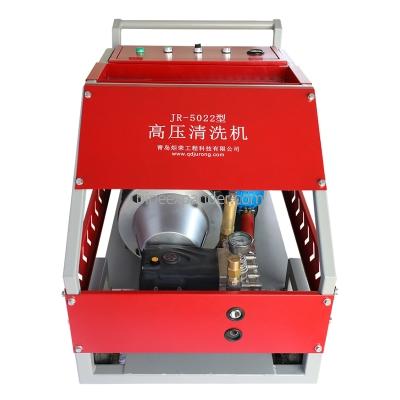

| Product Name | Model | Rated Pressure | Theoretical Flow Rate | Power | Power Type | Speed | Water Inlet Temp. | Dimensions | Weight |

| 500kg High-Pressure Cleaning Machine | FJJR-5022 | 500 bar | 22 L/min | 22 kW | 380V, 50Hz | 1450 rpm | ≤60°C | 113×65×85 cm | 284 kg |