These knowledge about the tube expander, we must understand!

When it comes to bulging tubes, we're basically confused. What is it? In fact, most of us do not understand the expansion of the tube and the expansion of the tube process, but it plays a very important role in our daily life, many products are inseparable from the use of expansion. Today we have sorted out some of the characteristics of the tube expander, the use of methods and precautions, hope to be useful to you!

What is a tube expansion

Tube expansion process has a wide range of applications in power plants, generally used in the two media exchange heat occasions. Tube expansion technology is applied to condenser, oil cooler, heater and other equipment in power plant. It is to expand the copper tube on the tube plate to become a device that can separate hot and cold working medium for heat exchange.

Since the expansion of the tube is a working process in which the tube is plastic deformed by the expansion force of the tube expander, the strength of the expansion joint is low, the pressure is limited, and the scope of use is limited. The process is simple to operate, low cost, and because of the small expansion strength, easy maintenance, so it is still used.

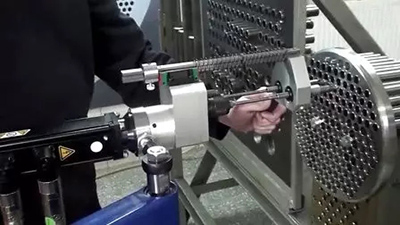

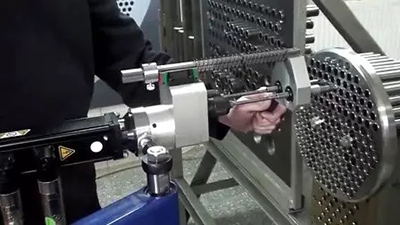

The hydraulic tube expander is mainly composed of three components: expansion shell (maintainer), expansion bead (steel ball) and expansion rod (mandrel). The expansion bead and expansion rod are made of Gcr15 bearing steel, and the expansion shell is made of 45# medium carbon steel by thermal solution process, improving the Angle (HRC55° ~ 60°) and toughness. The inner eight-figure trapezoidal inclined groove is opened on the expansion shell to prevent the expansion bead from falling. When working, the expansion pipe is placed into the expanded pipe (the expansion shell enters about two-thirds), push the expansion rod, turn the expansion rod counterclockwise (the batch expansion pipe should be made by the expansion machine), the expansion rod exerts the expansion bead, and the expansion bead then exerts the expansion shell. The curling Angle between the inclined groove of the expansion shell and the pipe pulls the expansion rod along the axis of the pipe while curling; With the gradual promotion of the expansion rod with taper, the inner hole and outer diameter of the expanded rod are gradually expanded, so that it is closely combined with the tube plate to reach the means of connection.

Characteristics of hydraulic tube expander

When the hydraulic tube expander is working, the full thickness of any thin and thick tube plate is uniformly expanded;

For any depth of core tube plate or multi-tube plate heat exchanger expansion;

For the inner fingerprint tube or seam welding absorption expansion;

The expansion pressure can be measured in practice, and the use of computers to perform full process control;

No damage to the pipe bridge after expansion, no reflection of the expansion effect of the expanded joint around;

The surplus stress after expansion is low, and stress erosion will not occur casually;

The axial direction after the expansion of the heat exchange tube is not extended but slightly extended, which is beneficial to add running music;

The fault of the inner hole of the external pipe is large, and the diameter of the expansion rod can be adjusted on the spot;

No oil purification at the joint, support the first expansion after welding new technology;

The edge of the heat exchanger with the tube box can be indirectly expanded, which is extremely convenient;

The hydraulic tube expansion machine operating system only weighs 2Kg, can be held by a single hand quickly expansion, the progress can reach four to six/min;

The "low-pressure expansion rod" integrated design of wearing parts can increase the trouble of frequent exchange of "rod, bag, ring, ring", and greatly promote its material power to a certain level.

Method of using tube expander

Straight tube, flanging, deep hole, bearing type four kinds of tube expander must first withdraw the expansion shell to the small head of the expansion rod, and then extend the expansion rod into the tube, and then push the expansion rod, so that the expansion rod, the expansion bead, the inner wall of the tube are pressed each other, and then use a ratchet wrench or the expansion machine to drive the expansion rod to rotate clockwise, the expansion rod will automatically push forward, the expansion bead will rotate in the opposite direction, and the inner wall of the tube will be rolled. Force the tube wall metal extension pipe diameter to increase until the expansion requirements are reached. When exiting, just rotate the expansion rod counterclockwise, the expansion rod will automatically exit, and can be removed from the tube after loosening.

Before expansion, the adjustable tube expander must adjust the positioning sleeve to the appropriate position by adjusting the nut according to the requirements of the expansion length, tighten the positioning screw, and then use it according to the above four operating methods of the tube expander.

Before expansion, the deep-hole adjustable tube expander must adjust the positioning sleeve to the appropriate position by adjusting the nut according to the expansion depth size, tighten the locking nut, and then use according to the operation method of the tube expander.

The three kinds of tube expanders of controlled straight, controlled flip and 90° silent flanging are all to control the size of the expansion rate by adjusting the screw sleeve, the expansion rate increases when the screw sleeve is rotated in, and the expansion rate decreases when the screw sleeve is rotated out, so the screw sleeve must be rotated out before expansion, but not to fall off, and then the test expansion is carried out according to the use of the above various tube expanders. After the expansion rate reaches the specified requirements, the tube can be formally expanded by fixing the position of the screw sleeve with a set screw.

Hydraulic tube expander maintenance and maintenance methods

Nowadays, how to deal with the failure of the hydraulic tube expander that we often use? How to protect it? Here is a brief introduction to the protection method of the hydraulic tube expander.

Operate the ratchet wrench (manual) or connector (intelligent control) set on the port of the expansion rod, let the standard needle direction rotate, complete the technical standard you need, the rotation position exit on the line. The tube expansion machine has control rotary equipment, conditioning tube expansion, should first adjust the required orientation and depth, and then, according to the above process after the completion of the tube expansion. Then clean the operable hydraulic tube expander with butter or oil, put it into the toolbox, store it in a dry place, prohibit moisture and rust the main parts of the tube expander are heat treated, high hardness, use must be placed with the expanded pipe, the expansion pipe work should be under the same pressure, to avoid the use of errors resulting in the expansion rod, expansion bead cracking and other appearance. Because it conflicts with the pipe and heats up, it will change the mechanical properties, so the hydraulic tube expander should be used alternately and some lubricating oil should be added appropriately to extend the service life.

German

German Spanish

Spanish French

French Italian

Italian Portuguese

Portuguese Japanese

Japanese Korean

Korean Arabic

Arabic Russian

Russian Indonesian

Indonesian Vietnamese

Vietnamese

Send Email

Send Email 008617372818528

008617372818528