Experience in heat exchanger installation and repair

Heat exchanger installation and repair

Heat exchanger is a static equipment used to transfer heat in chemical production. Two different media transfer heat in the heat exchanger, so that the larger temperature difference tends to decrease.

Heat exchangers are often used in chemical production as heaters, coolers, evaporators, etc.

The material of the heat exchanger can be metal materials (such as copper, aluminum, carbon steel, stainless steel, etc.), or non-metallic materials (such as graphite, glass, plastic, ceramics, etc.).

Heat exchangers commonly used in chemical production are tubular heat exchangers, jacket heat exchangers, snake tube heat exchangers, tube heat exchangers, corrugated plate heat exchangers, spiral plate heat exchangers, finned plate heat exchangers, graphite heat exchangers and new heat exchangers-heat pipes and so on.

There are many types of heat exchangers. This topic mainly introduces the structure of tubular heat exchangers and the repair methods of common faults.

Knowledge of tubular heat exchanger installation

Tubular heat exchanger is the most widely used heat exchanger in chemical production, its structure is relatively simple, high heat exchange efficiency, and strong adaptability (can be used under high or low temperature, high pressure or low pressure conditions).

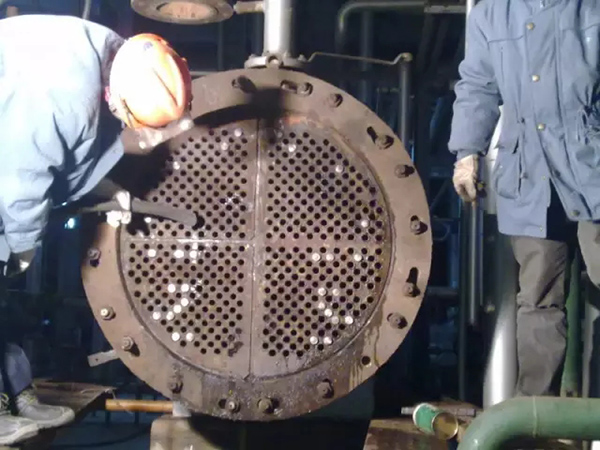

The main structure of a tubular heat exchanger is a tube bundle composed of many parallel tubes arranged in a cylindrical shell.

The two ends of the shell and the end cover are provided with flanges, and the end cover is connected with the shell by bolts.

The shell and the end cover are respectively provided with two medium inlet and outlet small flanges to facilitate the corresponding pipe connection.

The commonly used tubular heat exchangers in chemical production have several kinds of fixed tube plate, floating head type, U-shaped tube type and shell with heat compensation.

The main structure of the fixed tube-plate tube and shell heat exchanger:Head; Heat exchange tube; Baffle plate; The shell; A support; tubesheet

The tube plate (also called flower plate) forms a non-removable fixed connection with both ends of the housing.

The two ends of the pipe are connected with the tube plate by expansion welding. In order to change the flow direction of the medium between the pipes and improve the heat transfer efficiency, a number of baffle plates are arranged on the inner wall of the shell.

The end covers at both ends are connected with the shell in the form of flanges.

Two different media flow inside and between tubes.

In order to improve the heat exchange efficiency of the heat exchanger, a partition is sometimes set in the head to form a fluid distribution chamber, which constitutes the so-called double-tube tube heat exchanger or four-pass tube heat exchanger.

Pressure test until qualified.

After passing the pipe pressure test, install the head with gasket, and then carry out the pipe pressure test.

Installation of accessories

After the heat exchanger is installed and straightened, the pipes, valves and safety accessories can be installed. For the installation method, see installing pipes.

German

German Spanish

Spanish French

French Italian

Italian Portuguese

Portuguese Japanese

Japanese Korean

Korean Arabic

Arabic Russian

Russian Indonesian

Indonesian Vietnamese

Vietnamese

Send Email

Send Email 008617372818528

008617372818528