Tips of hydraulic pump station

A complete set of hydraulic system is composed of five major parts, that is, power components, executive components, control components, auxiliary components (accessories) and the working medium (hydraulic oil), of which the power components mainly refer to the oil pump in the hydraulic system, which can convert the mechanical energy of the prime mover into the pressure energy of the liquid, and thus provide power to the entire hydraulic system.

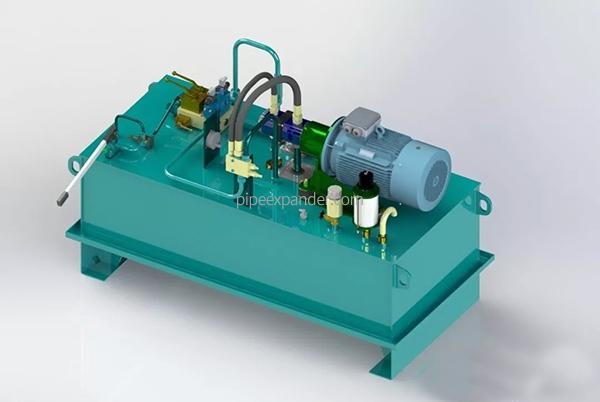

As the power source of the hydraulic system, the hydraulic pump station is a whole composed of a variety of elements and auxiliary parts, which can store a certain degree of cleanliness of the working medium for one or several systems, and output a certain pressure and flow of liquid power, as an integral hydraulic station installation hydraulic valve group base of the overall device.

Hydraulic pump station is one of the most important parts of the whole hydraulic system or hydraulic station. Its design quality and reasonableness of use and maintenance will have a great impact on the performance of hydraulic equipment.

Hydraulic pump station is usually composed of hydraulic pump group, fuel tank assembly, temperature control assembly, filter assembly and accumulator, a total of five components in an independent form, in order to meet the working characteristics of the machine and equipment and the rationality of the use of specific requirements, these accessories will have designers in a more reasonable form of specific components. For example, the liquid temperature gauge and filter assembly in the temperature control component are combined into a hydraulic oil tank as tank accessories.

In terms of composition,

The hydraulic pump group can be divided into hydraulic pump, prime mover (motor or internal combustion engine), coupling and transmission base, wherein the hydraulic pump is used to convert the mechanical energy of the prime mover into hydraulic energy, the prime mover is used to drive the hydraulic pump, the coupling is used to connect the prime mover and the hydraulic pump, and the transmission base is used to install and fix the hydraulic pump and the prime mover.

The oil tank assembly can be divided into the oil tank, the level gauge, the ventilation filter and the oil drain plug, wherein the oil tank is used to store the oil, distribute the oil heat, escape the air and remove the foam, install the components, the level gauge is used to display and observe the liquid level height, the ventilation filter is used to fill the oil and filter the air, the oil drain plug is used to clean the oil tank or replace the oil.

The temperature control component can be divided into oil thermometer, temperature sensor, heater and cooler, in which the oil thermometer is used to display and observe the oil temperature, the temperature sensor is used to detect and control the oil temperature, the heater is used for local heating of the oil, and the pit is used for cooling of the oil.

The accumulator assembly can be divided into an accumulator and a support bench. The accumulator is used to store energy, absorb hydraulic pulsation and shock, and the support bench is used to install the accumulator. In addition, the filter assembly is mainly used to separate solid particles in the oil to prevent blockage of small section channels and maintain the cleanliness of the oil.

Due to the wide range of uses of hydraulic pump station, its classification also has a lot of attention, generally can be concentrated in the layout, driving mode and output pressure level and flow characteristics of these three categories, between the layout mode needs a large number of examples to be explained, here do not repeat, this paper will focus on the drive mode, output pressure level and flow characteristics of these two.

Driving mode

①Electric type - This type of hydraulic pump station uses the motor as the prime mover, which is suitable for fixed mechanical equipment with stable power supply, and has low noise during work, so it is the most common application;

②Mobile type - This type of hydraulic pump station with diesel or gasoline engine as the prime mover, no power supply, easy to use in remote areas without power supply or circuit shortage and all kinds of construction equipment in field operations, but the noise is larger during work and the utilization rate is low;

③ Manual type - This type of hydraulic pump station is mainly operated by manpower, and can actually be seen as a hand pump, although its working efficiency is low, but it can supply oil to the small stroke hydraulic cylinder through simple piping, so it is often used with small presses, testing machines, pipe bending machines and rescue breaking equipment, hydraulic scissors and other manual machines and equipment. And can be used as a portable mobile source for motor vehicles.

Output pressure and flow characteristics

According to the output pressure of the hydraulic pump group, the hydraulic pump station can be divided into low pressure, medium pressure, high pressure, high pressure and ultra-high pressure, and the pressure value is:

Low pressure pumping station p≤2.5MPa,

Medium pressure pumping station p greater than 2.5 ~ 8MPa,

The medium and high pressure pumping station is p > 8 ~ 16MPa,

High pressure pumping station p > 16 ~ 32MPa,

The ultra-high pressure pumping station is p > 32MPa.

According to the output flow characteristics of the hydraulic pump group, the hydraulic pump station can be divided into quantitative type and variable type. If the hydraulic pump station is used, it can be equipped with a single quantitative pump or multiple quantitative pumps according to the demand of the hydraulic system for flow. If the variable type hydraulic pump station is used, it can be divided into constant power type, constant pressure type, constant flow type, pressure limiting type and pressure cut-off type according to the regulation characteristics of pressure - flow. Different output pressure and flow characteristics can be applied to different host working conditions and working needs.

In the actual use of engineering, most often choose pressure compensation variable pump oil supply, when the hydraulic system reaches the established pressure, the hydraulic oil is not from the relief valve high pressure overflow, but by reducing the flow output of the pump to achieve safety protection.

German

German Spanish

Spanish French

French Italian

Italian Portuguese

Portuguese Japanese

Japanese Korean

Korean Arabic

Arabic Russian

Russian Indonesian

Indonesian Vietnamese

Vietnamese

Send Email

Send Email 008617372818528

008617372818528